Calender roller

Polishing roller

Calender roller

Polishing roller

Execution as desired

Calender roller

Polishing roller

Execution as desired

Following surface requests can be realized on request:

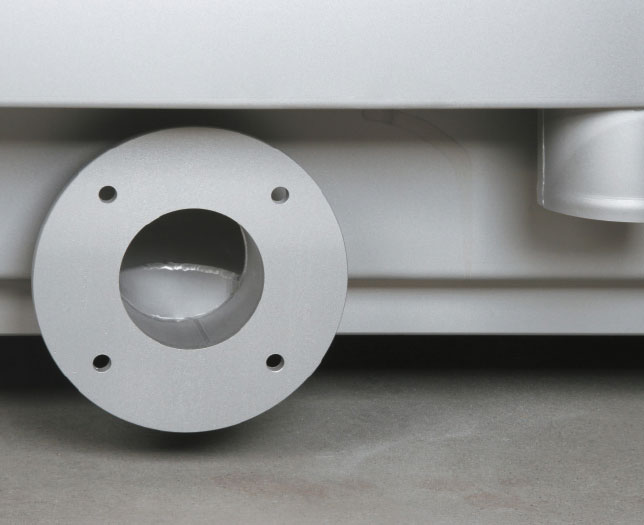

Standard nip roller

Synchronised pressure roller standard

|

|

|

|

|

|

10000 mmLength |

800 mmDiameter |

0,05 mmRadial run-out |

The roller made out of steel, which is for the transport of webs and endless conveyers used in the various production procedures, is a key component in mechanical engineering and construction.

With our modern machine tools specially tailored to this product, we are able to produce precise steel guide rollers with a few precisely defined process sequences, which meet or exceed the requirements of our customers with an optimized material usage.

Tambour rollers

Worker / turner

Fleece track

Cross lapper

Oven

5000 mmLength |

1200 mmDiameter |

0,05 – 0,03 mmRadial run-out |

Execution as desired

Execution as desired

Execution as desired

Execution as desired

Wire profile |

T-Profil 5×5 – 1.4571 |

I-Profil 7×3 – 1.4301 |

4 x 12 = 48 mm – 4thread

4 x 24 = 96 mm – 4thread

3 x 12 = 36 mm – 3thread

3 x 24 = 72 mm – 3thread

Radial run-out tolerance up to 0,5 mm

Finishing: polishing

Standard diameters = 80 – 220 mm

|

|

|

|

|

|

8000 mmL max |

219 mmStandard diameter |

2 – 4 mmWall thickness |

One of our core competences is the calibration of stainless steel tubes on accurate shape tolerances. With this procedure we can do without the costly machining of the tubes. The surface of the rollers is usually belt polished or according to specification coated, for example with non-stick coatings made out of PTFE, FEP or PFA.

Our modular build production process contains automated stations for the joining and welding of the bottom-shaft units, a series belt polishing station as well as an all-over quality control of every single guide roll on a special test bench with digital dial gauge and immediate reporting of the measured values.

Due to this production philosophy we are able to offer an overall solution that is highly attractive in terms of price and quality. We can proudly say:

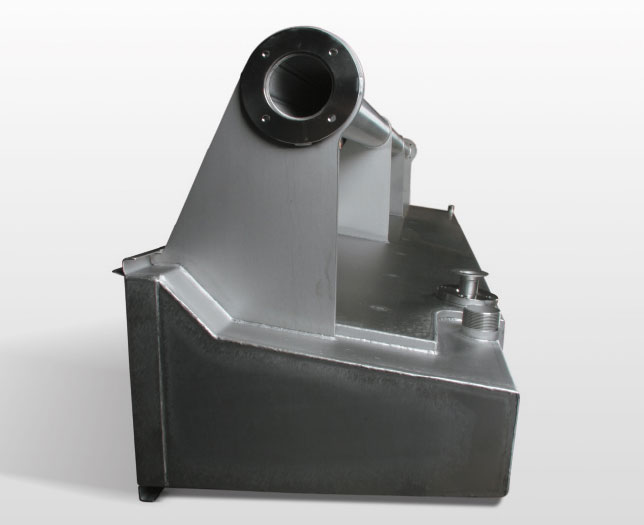

Single-coat cooling rollers

Double-coated cooling rolls with steel coating

Double-coated cooling rolls with stainless steel coating

1200 mmDiameter |

10000 mmLength |

550 mmWall thickness |

0,05 – 0,5 mmRadial run-out |

We manufacture this type of cooling roller with coatings, made of stainless steel or steel, whereby the steel rollers are usually given a coating for protection against corrosion. If we use our stainless steel guide roll production for the cooling rollers, the typical dimensions and geometric tolerances mentioned there, also apply to wall thicknesses of 2 – 5 mm.

The bottom-shaft units are mostly manufactured in welded construction, less often as screw construction. The water drainage can be designed on both sides as well as on one side with internal water return.

Depending on the requirements, the thick-walled roller sleeves are turned inside out in order to obtain a uniform wall thickness across the width and circumference. As a rule, however, this is not desired, since the best compromise between price and function is often in the foreground in the case of single-coat construction.

If the dimensions and tolerances permit, we therefore recommend our cooling rollers made of calibrated stainless steel tube, because a uniform wall thickness is guaranteed, since the sheet metal coat is not turned.

1200 mmDiameter |

4000 mmLength |

3 – 50 mmWall thickness |

0,05 – 0,5 mmRadial run-out |

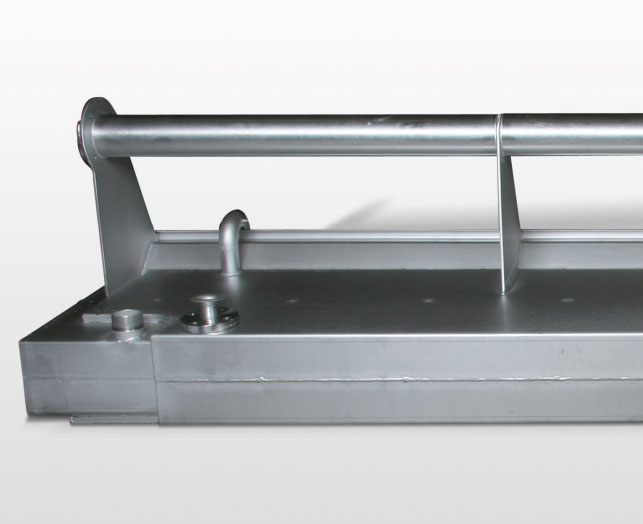

The use of double-coated cooling rolls is necessary, if a defined cooling of the web with minimal deviation of the temperature over length and width is important in the production process.

Due to the forced guidance of the cooling water in a helical channel, which is formed between the inner and outer coat of the cooling roller, the surface temperature of the cooling roller or the heat transfer to the web can be set very precisely. Depending on the requirement profile, the water ducts are arranged in co current or counter current. The internal structure of the cooling rollers can be specified by the customer or designed by our specialists according to the specified boundary conditions. On request, we can create the mechanical and thermal design of your cooling roller(s) including recommendations for rotary unions and roller bearings.

The materials used are again steel and stainless steel as a welded construction or with screwed pin base units.

1200 mmDiameter |

4000 mmLength |

3 – 5 mmWall thickness |

0,1 – 0,5 mmRadial run-out |

A speciality is cooling rollers with an inner body made of black steel and a thin-walled stainless steel outer coat. The outer sheaths are rounded from 3 – 5mm thick stainless steel sheet and shrunk warm onto the inner body without internal processing. The outer coat adapts to the shape of the inner body and after finishing, this coat has a very uniform wall thickness. With this design, we achieve radial run out accuracies of 0.1 – 0.5 mm and are therefore able to offer a double-coated cooling roller at a very good price-performance ratio, which can be used in many production processes. The decisive advantage: The surface of the cooling roll is 100% corrosion-protected without subsequent coating. The usual, expensive and time-consuming chrome plating is completely eliminated.