8000 mmL max |

219 mmStandard diameter |

2 – 4 mmWall thickness |

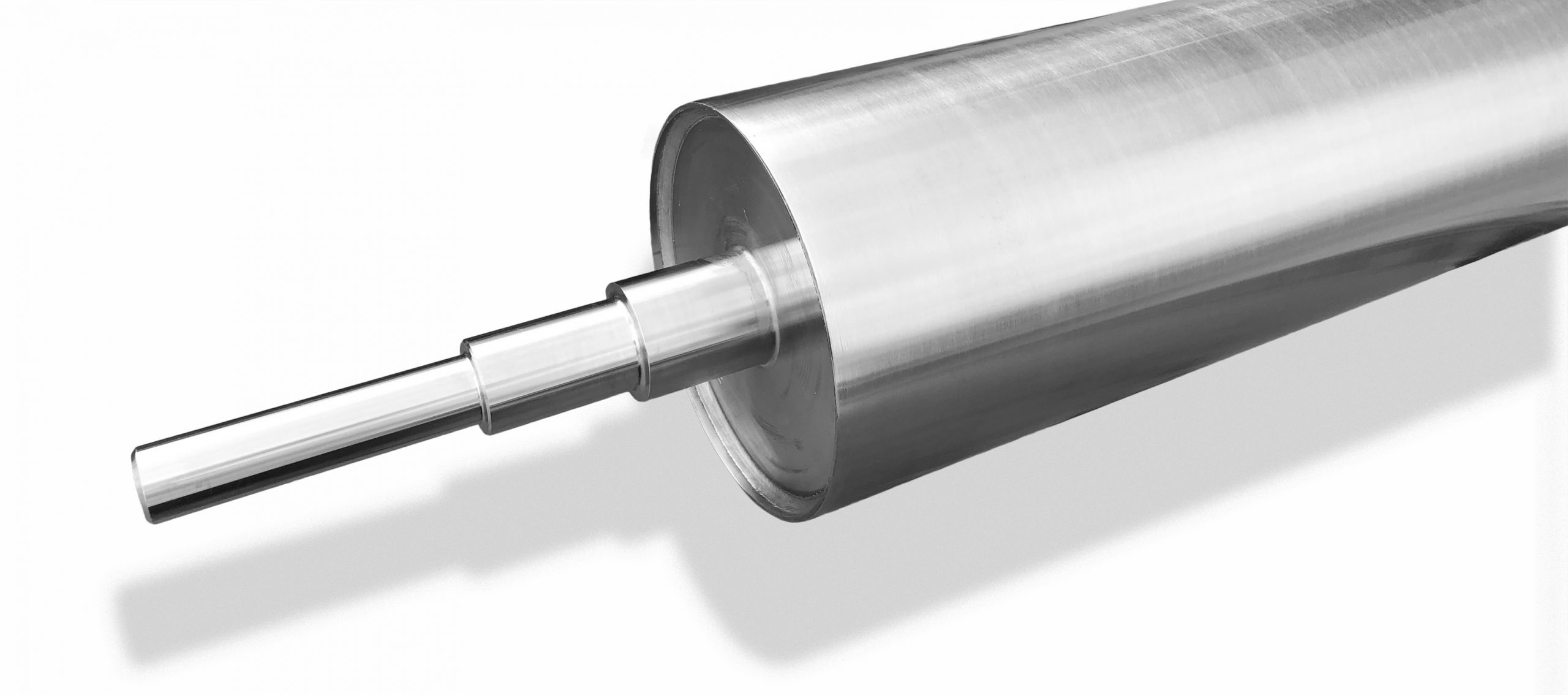

- Made of calibrated, longitudinal welded tubes

- Material: 1.4301 or 1.4404 (AISI 304, AISI 316)

- Radial run-out tolerance depending on length and diameter up to 0,3 mm

- Standardized surface treatments: Belt grinding

- Other surface treatments on request

- Control on concentricity with automatic measuring devices

- Each roller is assigned a measuring protocol

- Maximum length 8000 mm

- Storing standard diameters 80-219 mm

- 2-4 mm wall thickness

- Further dimensions can be delivered at request

One of our core competences is the calibration of stainless steel tubes on accurate shape tolerances. With this procedure we can do without the costly machining of the tubes. The surface of the rollers is usually belt polished or according to specification coated, for example with non-stick coatings made out of PTFE, FEP or PFA.

Our modular build production process contains automated stations for the joining and welding of the bottom-shaft units, a series belt polishing station as well as an all-over quality control of every single guide roll on a special test bench with digital dial gauge and immediate reporting of the measured values.

Due to this production philosophy we are able to offer an overall solution that is highly attractive in terms of price and quality. We can proudly say: